PRESS FOR WAX OPERCLES AND FRUIT - SCREW Ø 20 cm - STAINLESS STEEL CAGE - painted steel support Suitable for manual squeezing of the opercles of Wax, Fruit, Pomace, Myrtle, etc. Tilting frame for easier use Cage size: 20 x 35 cm Cage Capacity : 9 L Weight: 10 kg MADE IN ITALY

PRESS FOR WAX OPERCLES AND FRUIT - SCREW Ø 20 cm - STAINLESS STEEL CAGE - painted steel support Suitable for manual squeezing of the opercles of Wax, Fruit, Pomace, Myrtle, etc. Tilting frame for easier use Cage size: 20 x 35 cm Cage Capacity : 9 L Weight: 10 kg MADE IN ITALY

PRESS FOR WAX OPERCLES AND FRUIT - SCREW Ø 20 cm - STAINLESS STEEL CAGE - painted steel support Suitable for manual squeezing of the opercles of Wax, Fruit, Pomace, Myrtle, etc. Tilting frame for easier use Cage size: 20 x 35 cm Cage Capacity : 9 L Weight: 10 kg MADE IN ITALY

PRESS FOR wax or POMACE - Ø 25 cm - Ratchet with 1-speed mechanical movement - Pressed steel basin - High resistance steel screw - Beech wood staves fixed with through bolts - equipped with 6 caps and 2 crescents.

Dimensions : Cage 25 x 40 cm - capacity 20 L Screw diameter 28 mm Weight 22 Kg MADE IN ITALY

PRESS FOR wax or POMACE - Ø 25 cm - Ratchet with 1-speed mechanical movement - Pressed steel basin - High resistance steel screw - Beech wood staves fixed with through bolts - equipped with 6 caps and 2 crescents.

Dimensions : Cage 25 x 40 cm - capacity 20 L Screw diameter 28 mm Weight 22 Kg MADE IN ITALY

PRESS FOR wax or POMACE - Ø 25 cm - Ratchet with 1-speed mechanical movement - Pressed steel basin - High resistance steel screw - Beech wood staves fixed with through bolts - equipped with 6 caps and 2 crescents.

Dimensions : Cage 25 x 40 cm - capacity 20 L Screw diameter 28 mm Weight 22 Kg MADE IN ITALY

PRESS FOR wax or POMACE - Ø 35 cm - Ratchet with 1-speed mechanical movement - Pressed steel basin - High resistance steel screw - Beech wood staves fixed with through bolts - equipped with 6 caps and 2 crescents.

Dimensions : Cage 35 x 50 cm - capacity 48 L Screw diameter 35 mm Weight 57 Kg MADE IN ITALY

PRESS FOR wax or POMACE - Ø 35 cm - Ratchet with 1-speed mechanical movement - Pressed steel basin - High resistance steel screw - Beech wood staves fixed with through bolts - equipped with 6 caps and 2 crescents.

Dimensions : Cage 35 x 50 cm - capacity 48 L Screw diameter 35 mm Weight 57 Kg MADE IN ITALY

PRESS FOR wax or POMACE - Ø 35 cm - Ratchet with 1-speed mechanical movement - Pressed steel basin - High resistance steel screw - Beech wood staves fixed with through bolts - equipped with 6 caps and 2 crescents.

Dimensions : Cage 35 x 50 cm - capacity 48 L Screw diameter 35 mm Weight 57 Kg MADE IN ITALY

FILTER BAG for centrifuge with COARSE mesh (1300 micron) for 30 L CENTRIFUGE (Cod. QI C100)

FILTER BAG for centrifuge with COARSE mesh (1300 micron) for 30 L CENTRIFUGE (Cod. QI C100)

FILTER BAG for centrifuge with COARSE mesh (1300 micron) for 30 L CENTRIFUGE (Cod. QI C100)

FILTER BAG for centrifuge with thin mesh (1300 micron) for 30 L CENTRIFUGE (Cod. QI C100)

FILTER BAG for centrifuge with thin mesh (1300 micron) for 30 L CENTRIFUGE (Cod. QI C100)

FILTER BAG for centrifuge with thin mesh (1300 micron) for 30 L CENTRIFUGE (Cod. QI C100)

Handcrafted wooden letterbox - MEASURES: L 43 cm - D 24 cm - H 40 cm To be used as a mailbox or for window dressing or for external point of sale use

Handcrafted wooden letterbox - MEASURES: L 43 cm - D 24 cm - H 40 cm To be used as a mailbox or for window dressing or for external point of sale use

Handcrafted wooden letterbox - MEASURES: L 43 cm - D 24 cm - H 40 cm To be used as a mailbox or for window dressing or for external point of sale use

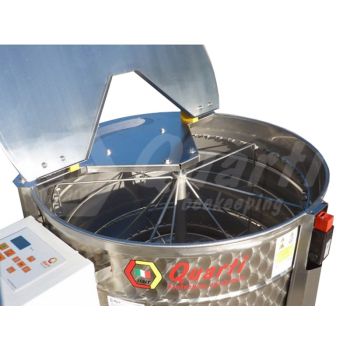

DISOPRESS 2 is a compact professional machine that speeds the uncapping process. The machine consists of the uncapping machine with heated vibrating knives "Giordan" (code 170K) and the operculum press. DISOPRESS 2 is made entirely of AISI 304 stainless steel and works by means of the guided passage of the frames through two water-heated vibrating knives that allow to obtain a precise and optimal cut of the operculum. With the uncapping machine the opercula are not crumbled but cut, as with the use of a manual knife. With the addition of the double blade kit there is no need to re-trim the frames after the uncapping process.

After uncapping, the operculum removed from the frames is unloaded under the uncapping machine where the operculum press unit is installed. The press is made entirely of AISI 304 stainless steel and works cold through a perforated net containing an auger that presses the operculum.

DISOPRESS 2 is a compact professional machine that speeds the uncapping process. The machine consists of the uncapping machine with heated vibrating knives "Giordan" (code 170K) and the operculum press. DISOPRESS 2 is made entirely of AISI 304 stainless steel and works by means of the guided passage of the frames through two water-heated vibrating knives that allow to obtain a precise and optimal cut of the operculum. With the uncapping machine the opercula are not crumbled but cut, as with the use of a manual knife. With the addition of the double blade kit there is no need to re-trim the frames after the uncapping process.

After uncapping, the operculum removed from the frames is unloaded under the uncapping machine where the operculum press unit is installed. The press is made entirely of AISI 304 stainless steel and works cold through a perforated net containing an auger that presses the operculum.

DISOPRESS 2 is a compact professional machine that speeds the uncapping process. The machine consists of the uncapping machine with heated vibrating knives "Giordan" (code 170K) and the operculum press. DISOPRESS 2 is made entirely of AISI 304 stainless steel and works by means of the guided passage of the frames through two water-heated vibrating knives that allow to obtain a precise and optimal cut of the operculum. With the uncapping machine the opercula are not crumbled but cut, as with the use of a manual knife. With the addition of the double blade kit there is no need to re-trim the frames after the uncapping process.

After uncapping, the operculum removed from the frames is unloaded under the uncapping machine where the operculum press unit is installed. The press is made entirely of AISI 304 stainless steel and works cold through a perforated net containing an auger that presses the operculum.