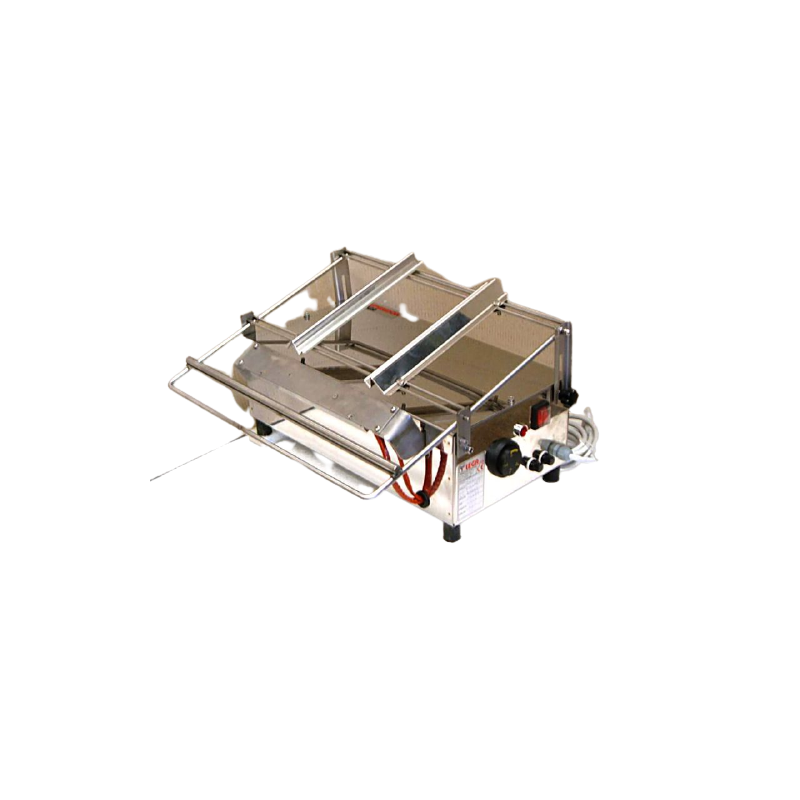

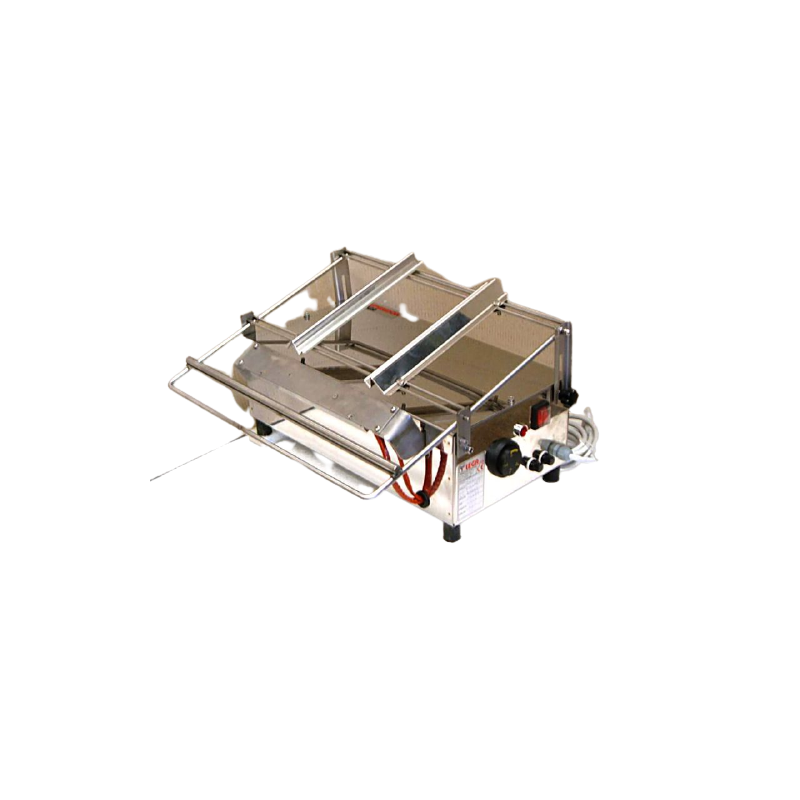

ELECTRIC benchtop DISOPERCULATOR with horizontal vibrating blade Made of stainless steel, very quiet, with the serrated-edge blade 300 mm long, Electrically heated, controlled by thermostat and oscillating horizontally by means of a small gear motor ALIM. 220 V-50 Hz Capacity of 150 combs/hour. Works perfectly resting on our uncapping benches or uncapping carriage.

Its operation is simple: just slide the honeycomb to be uncapped onto the frame guides from top to bottom, passing first one face then the other on the blade. The opercula cut in this way fall onto the bench's drip pan. The different inclination of the frame varies the incidence of the blade thus the depth of cut. When the frame is fully tilted, the blade cuts flush with the wood. The frame supports can be changed in support width to fit any size. The thermostat allows the cutting blade temperature to be changed to select the optimum temperature for uncapping frames. A practical and compact uncapping machine for those who have few Beehives but want to rely on the precision of a mechanical blade. The electric benchtop uncapping machine is designed to be placed on our workbenches. With this uncapping machine you can process up to 150 frames in an hour, allowing you to speed up your work. Designed and manufactured inside our factory, the benchtop uncapping machine is the result of Made in Italy quality and all Lega experience. ADVANTAGES Easy to use Easy to clean Silent Made in Italy Durable over time TECHNICAL CHARACTERISTICS Manufacture: Stainless steel AISI 304 Maximum dimensions: 520x420x250 mm Motor power: 250 W Electrical absorption: 880 W Power supply voltage: 220 V Frequency: 50 Hz Temperatures reached: 40° to 120° C Production capacity: 150 frames/h Weight: 15 kg *The supports and adjusting screws are plastic

28 cm stainless steel serrated blade uncapping knife with wooden handle

Stainless steel blade with heat sink Blade length cm 27 Blade width cm 5.3 Indicator light-on-off Automatic internal thermostat Nylon handle with fiberglass 230 V-120 W Warranty 1 year

28 cm stainless steel serrated blade uncapping knife with wooden handle

Stainless steel blade with heat sink Blade length cm 27 Blade width cm 5.3 Indicator light-on-off Automatic internal thermostat Nylon handle with fiberglass 230 V-120 W Warranty 1 year

28 cm stainless steel serrated blade uncapping knife with wooden handle